Direct naar..

Uitvoeringsprogramma

In 2024 startte het derde Topsectorprogramma. Sinds het begin van de Topsector Logistiek in 2012 zijn er grote stappen gezet. De scope van het programma is verbreed van primair het vergroten van het economisch verdienvermogen van de logistiek naar daarnaast de inzet op maatschappelijke doelen ten behoeve van leefbaarheid, zoals verduurzaming en circulaire economie.

Toepassingsgebieden

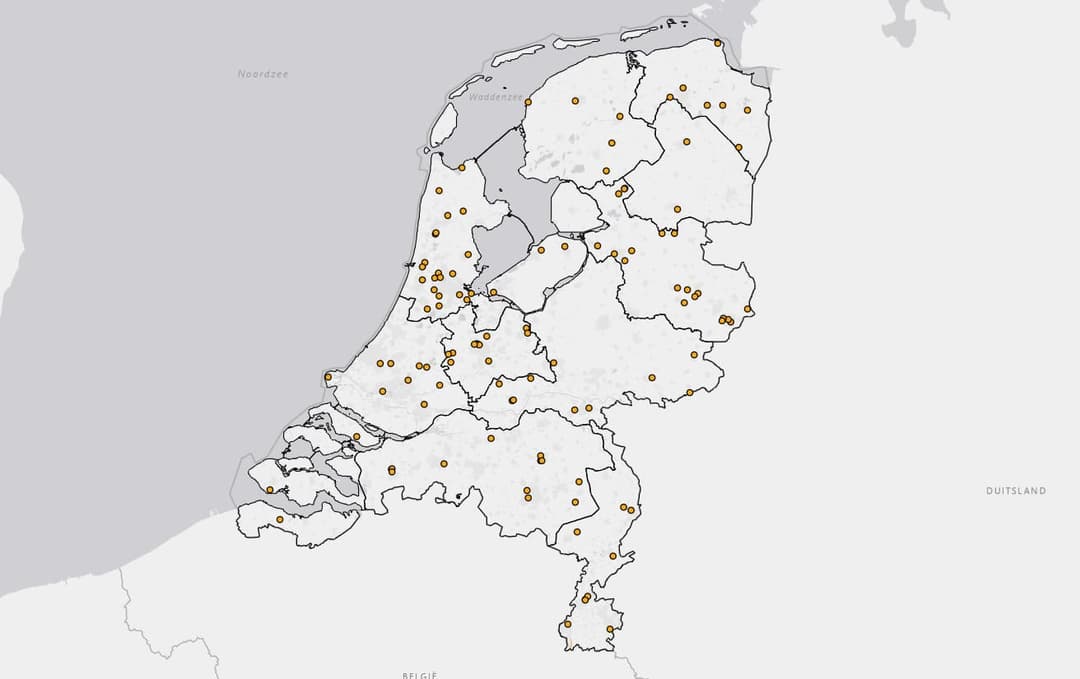

De Topsector Logistiek kent vier verschillende toepassingsgebieden, namelijk: Mobiele Werktuigen & Bouwlogistiek, Multimodaal goederenvervoer, Steden & Ruimte en Supply Chains. Ieder toepassingsgebied heeft een eigen focus en de uitvoering van het programma wordt door een stuurgroep aangestuurd. Bekijk hieronder per toepassingsgebied het programma en doelstellingen.

Projectresultaten

Wij vinden het belangrijk dat opgedane kennis en ervaring in projecten breed beschikbaar is, zodat iedereen in de logistiek hiermee zijn voordeel kan doen. Bekijk via ons nieuwsoverzicht de lopende activiteiten. Alle afgeronde projecten kunt u terugvinden in onze kennisbank.Over Topsector Logistiek

Nederland doet internationaal goede zaken met handel en industrie. Om deze toppositie te behouden moet Nederland concurrerend blijven. Dat doen we onder andere door te investeren in de tien topsectoren, missies voor de toekomst en sleuteltechnologieën. Topsector Logistiek is een van die tien topsectoren. Sinds 2011 werken ondernemers binnen topsectoren nauw samen met wetenschappers en de overheid.